July 11, 2019

Are you aware of the fact that approximately $4.5 trillion industries across the globe could not survive without the use of electronic cer...

The Application Of Electronic Ceramic Components In The Electronic Industry

The Application Of Electronic Ceramic Components In The Electronic Industry

The Application Of Electronic Ceramic Components In The Electronic Industry

8

10

99

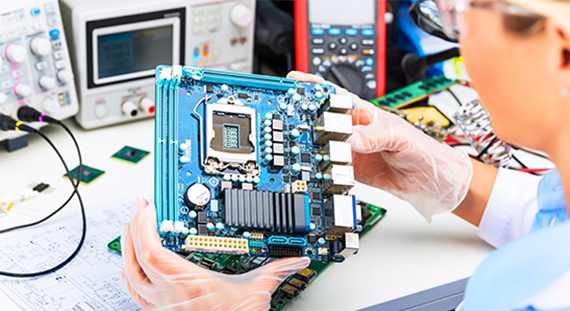

Are you aware of the fact that approximately $4.5 trillion industries across the globe could not survive without the use of electronic ceramic components?

The use of ceramic based electronic components cannot be denied in industries that manufacture smartphones, electronics such as television sets, digital computers, and various other automotive electronics. The ceramic based electronic components are also extensively used in the medical industry.

Electrical conductivity of the ceramic components

The ability of a metal to produce an electric current is termed as electrical conductivity of a particular metal. Ceramic metals come in a wide variety. Most of the ceramic components are dielectric in nature.

The electrical conductivity of ceramic metals depends on the frequency of its application. Temperature of the metal also plays a great role in determining the conductivity of the ceramic.

The Electronic Ceramic Components that are used as electrical insulators across industries are inclusive of hermetic packaging, protective components, spark plugs, and ceramic arc tubes. These parts are most commonly used for covering power lines and wires without a covering.

The electronic ceramic components are widely used in various applications in industries such as aerospace, marine, transportation, and automobiles.

The superconducting properties of ceramics

The ceramics are very low on electrical conductivity. But some of the ceramics also possess superconducting properties. For example, Lanthanum-barium-copper oxide is a ceramic which may produce electric currents at high degrees such as 138K.

This type of superconductor ceramic is also known as High Temperature Superconductors.

What are the magnetic properties of ceramic?

The magnetic ceramics are produced by making use of sintering technology. In this, the iron oxide and strontium carbonates are mixed with small quantities of other metal oxides.

The name used for magnetic ceramics is Ferrites. The two main types of magnetic ceramics are as follows:

- Anisotropic ceramic magnets

- Isotropic ceramic magnets

The usage of Electronic Ceramic Components is extensive across numerous industries such as aerospace, transmission, communication, and many others. More and more people nowadays are making use of ceramic components in the electronic industry.

Subscribe to:

Post Comments (Atom)

The Benefits of X-Ray Inspection Equipment in Quality Control.

Assuring product quality is of utmost importance to businesses in today's industrial world. One tool that has gained popularity for qu...

Labels

- Ac-Dc converter

- Advanced IC Sockets

- Buy Military Components

- Buy Passive Components

- Capacitors

- Ceramic capacitor

- Component

- component suppliers

- components distributor

- components suppliers

- Components Visual Inspection

- Counterfeit Electronic

- Counterfeit electronic chips

- counterfeit electronic components

- Counterfeit Electronics Personnel Training

- Counterfeit Mitigation

- counterfeiting

- Distributor

- Electrical Visual Inspections

- electronic

- electronic ceramic components

- Electronic Component

- Electronic Component Distributors

- Electronic Component Distributors Military Electronic Parts Electronic

- Electronic Component Distributors Military Electronic Parts Electronic Components Suppliers Buy Passive Components

- Electronic components

- electronic components brokers

- Electronic Components Counterfeit Mitigation

- electronic components distributor

- electronic components distributor in usa

- Electronic Components Suppliers

- electronic products

- Inspection Equipments

- Integrated Supply chain solutions

- Intervox Speakers

- Inventory

- inventory control

- inventory control and management

- Inventory Management

- Inventory Management Challenges

- Inventory Management Solution

- inventory management solutions

- inventory management system

- IP-66

- M3-17

- Manufacture

- military component

- military component suppliers

- Military Electronic Parts

- obsolete component suppliers

- obsolete components distributor

- Obsolete Electronic Components

- Obsolete Electronic Components Distributor

- Proactive Product Supplier Lifecycle Management

- Resonator Parts

- rohs compliance testing

- RoHS Testing

- RoHS Testing Equipment

- Supply Chain Management

- UNIMAX Switches

- Visual Inspection

- Visual Inspection Components

- visual inspection equipment

- Visual Inspection Equipments

- Visual Inspection System

- x ray inspection equipment

- X-Ray inspection

- X-Ray inspection equipment

- X-Ray Inspection Systems

- X-Ray inspection Testing

- X-Ray Testing & Inspection Equipment

- x-ray-imaging

0 comments: