Inventory management is a crucial component of the supply chain distribution and manufacturing process. The inventory needs to be well-maint...

Mistakes to avoid for improving inventory management!

March 2022

Inventory management is a crucial component of the supply chain distribution and manufacturing process. The inventory needs to be well-maintained throughout the different phases from sourcing, storing, transferring to manufacturing for maintaining excellent quality control. Any mistakes in maintaining the inventory management system may lead to inventory management challenges such as loss of inventory, inventory damages, etc., affecting the production. Thus, manufacturers and distributors need to be aware of the common mistakes and avoid them to ensure excellent inventory management.

Following are the top inventory management mistakes you should avoid:

- Manually managing inventory

Businesses that continue to manage the inventory through manual processes face more inventory management challenges as there are higher chances of human error. As a result, they may struggle to keep an accurate inventory record. Moreover, such errors may reduce the efficiency of business operations. Thus, it is best to adopt an automated inventory management system to optimize the inventory management process.

2. Using obsolete inventory tracking technology

Many businesses become reluctant to employ the latest technology inventory management solutions to save costs. Instead, they continue to use obsolete inventory tracking technology. As a result, their inventory management process becomes outdated and inefficient eventually. Moreover, inventory tracking through old technologies such as spreadsheets or obsolete software may keep them behind the competitors in today's competitive markets. Thus, it is crucial to invest in up-to-date inventory management solutions that are fully equipped with automated updates, accurate tracking, and instant accessibility.

3. Poor integration of inventory management system

Sometimes businesses

invest in various separate systems for each process from storing, inspections,

moving parts, tracking, etc. If these technologies are not integrated using a

centralized inventory management system, it can increase the administrative

burden. In that case, instead of boosting business productivity, it may slow

down the inventory management process. Therefore, it is recommended to consider

employing an inventory management system that can easily integrate various

technologies while allowing centralized control.

If you are looking to invest in an up-to-date, efficient inventory management system to cope with various inventory challenges, get in touch with our team to explore our innovative inventory management solutions today!

Looking for a replacement part, obsolete electronic parts, or other electronic components that are in shortage in the electronic components ...

Tips when buying obsolete electronic components from independent distributors!

March 2022

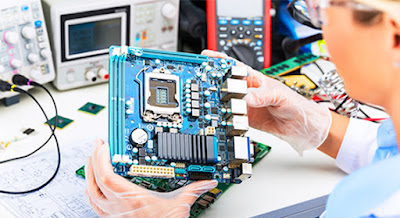

Looking for a replacement part, obsolete electronic parts, or other electronic components that are in shortage in the electronic components supply chain can be highly challenging. It is no secret that many unreliable suppliers in the supply chain provide counterfeit electronic components. However, when you can’t buy these parts from the original manufacturer, you may need to rely on an independent third-party supplier for fulfilling your inventory needs. Therefore, it is crucial to verify that you are sourcing parts from legitimate and reliable electronic components distributors.

Here we have a list of things you should consider when you have to buy obsolete electronic components from an independent electronic components distributor to protect yourself against counterfeit products:

- Verify industry certifications

The electronic component distributors must adhere to industry-specific certifications such as ISO (International Standards Organization) to distribute specific electronic components. Thus, verifying that the distributor has an ISO certification is recommended to signify the supplier complies with the ISO quality management system. In addition, you can ensure the vendor’s legitimacy by checking if they are a member of the ERAI.

- ANSI/ESD S20.20 certification

If you want to buy electronic components for applications in the aerospace, automotive, telecommunication, commercial electronic, and medical equipment industries, you must verify that the distributor is ANSI/ESD S20.20 certified.

- High-quality Inventory

It is crucial to ensure that the supplier you choose features a high-quality electronic components inventory. Thus, it is best to ask the distributor regarding their quality assurance process. For example, it is recommended to gather information regarding whether they have a fully equipped facility with appropriate inventory management measures such as a moisture sensitivity program to ensure that the obsolete electronic components are stored safely. In addition, it is best to ensure the supplier complies with IDEA-STD-1010, AS6081, and other industry-specific quality assurance processes.

- Counterfeit mitigation process

Although some buyers may have an in-house counterfeit inspection team, it is not the case for most. In that case, it may benefit you to source electronic components from an independent distributor (such as Resion), which has in-house Intercept inspectors and advanced technology equipment for visual inspections, electrical testing, X-ray testing & other counterfeit mitigation measures to ensure delivering authentic parts.

- Check online reviews

You can also verify if the vendor is legitimate by researching the supplier’s reputation online. Ensure to check the electronic components distributor’s website and check online reviews by previous buyers of the company to determine whether they deliver genuine and high-quality products.

- Additional information

Before making the final purchase decision, it is recommended to discuss every aspect, including the source of the obsolete part, required documentation, waiting time, minimum order limit, delivery details, and payment procedure. It will give you an idea of when to expect the product to arrive and make arrangements accordingly for future re-ordering.

Finding a reliable and trusted independent supplier beforehand can save you from a lot of trouble whenever you may immediately require replacement for any obsolete parts in the future. Thus, it is recommended to keep a list of various independent electronic components distributors handy.

If you are looking for

an obsolete electronic component distributor that fulfills the above criteria

and is a reputable and legitimate supplier, simply contact our team for expert

assistance! Explore our extensive electronic components inventory today!

The Benefits of X-Ray Inspection Equipment in Quality Control.

Assuring product quality is of utmost importance to businesses in today's industrial world. One tool that has gained popularity for qu...

Labels

- Ac-Dc converter

- Advanced IC Sockets

- Buy Military Components

- Buy Passive Components

- Capacitors

- Ceramic capacitor

- Component

- component suppliers

- components distributor

- components suppliers

- Components Visual Inspection

- Counterfeit Electronic

- Counterfeit electronic chips

- counterfeit electronic components

- Counterfeit Electronics Personnel Training

- Counterfeit Mitigation

- counterfeiting

- Distributor

- Electrical Visual Inspections

- electronic

- electronic ceramic components

- Electronic Component

- Electronic Component Distributors

- Electronic Component Distributors Military Electronic Parts Electronic

- Electronic Component Distributors Military Electronic Parts Electronic Components Suppliers Buy Passive Components

- Electronic components

- electronic components brokers

- Electronic Components Counterfeit Mitigation

- electronic components distributor

- electronic components distributor in usa

- Electronic Components Suppliers

- electronic products

- Inspection Equipments

- Integrated Supply chain solutions

- Intervox Speakers

- Inventory

- inventory control

- inventory control and management

- Inventory Management

- Inventory Management Challenges

- Inventory Management Solution

- inventory management solutions

- inventory management system

- IP-66

- M3-17

- Manufacture

- military component

- military component suppliers

- Military Electronic Parts

- obsolete component suppliers

- obsolete components distributor

- Obsolete Electronic Components

- Obsolete Electronic Components Distributor

- Proactive Product Supplier Lifecycle Management

- Resonator Parts

- rohs compliance testing

- RoHS Testing

- RoHS Testing Equipment

- Supply Chain Management

- UNIMAX Switches

- Visual Inspection

- Visual Inspection Components

- visual inspection equipment

- Visual Inspection Equipments

- Visual Inspection System

- x ray inspection equipment

- X-Ray inspection

- X-Ray inspection equipment

- X-Ray Inspection Systems

- X-Ray inspection Testing

- X-Ray Testing & Inspection Equipment

- x-ray-imaging

0 comments: